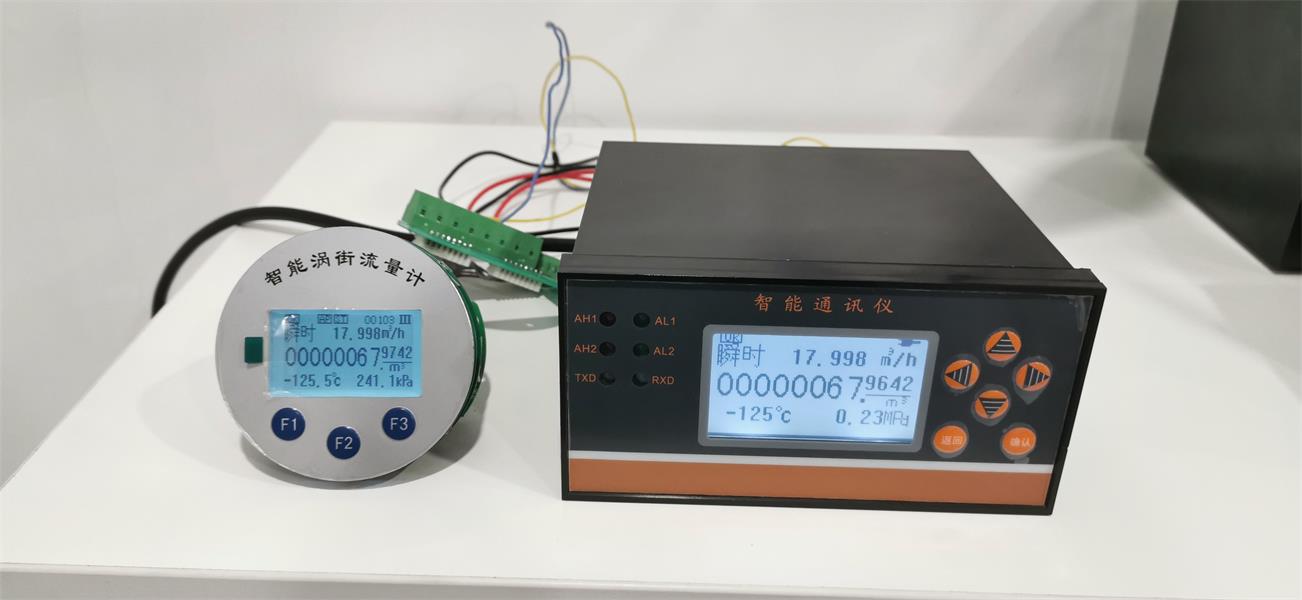

Intelligent communication device

Product Overview

The intelligent communication device collects digital signals from the flowmeter through the RS485 interface, effectively avoiding transmission errors of analog signals. The primary and secondary meters can achieve zero error transmission;

Collect multiple variables and simultaneously collect and display data such as instantaneous flow rate, cumulative flow rate, temperature, pressure, etc. Suitable for secondary transmission display of instruments equipped with RS485 communication function.

The communication device is connected to vortex flow meters, vortex flow meters, gas turbine flow meters, gas waist wheel (Roots) flow meters, etc., with RS485 transmission for accurate measurement.

Main Features

Main Technical Indicators Of Instruments

1. Input signal (customizable according to customer protocol)

● Interface method - Standard serial communication interface: RS-485 (communication interface with primary meter);

● Baud rate -9600 (the baud rate for communication with the primary meter cannot be set, as indicated by the meter type).

2. Output signal

● Analog output: DC 0-10mA (load resistance ≤ 750 Ω)· DC 4-20mA (load resistance ≤ 500 Ω);

3. Communication output

● Interface method - Standard serial communication interface: RS-232C, RS-485, Ethernet;

● Baud rate -600120024004800960Kbps, set internally in the instrument.

4. Feed output

● DC24V, load ≤ 100mA· DC12V, Load ≤ 200mA

5. Characteristics

● Measurement accuracy: ± 0.2% FS ± 1 word or ± 0.5% FS ± 1 word

● Frequency conversion accuracy: ± 1 pulse (LMS) is generally better than 0.2%

● Measurement range: -999999 to 999999 words (instantaneous value, compensation value);0-99999999999.9999 words (cumulative value)

● Resolution: ± 1 word

6. Display mode

● 128 × 64 dot matrix LCD graphic display with backlight large screen;

● Accumulated flow rate, instantaneous flow rate, accumulated heat, instantaneous heat, medium temperature, medium pressure, medium density, medium enthalpy, flow rate (differential current, frequency) value, clock, alarm status;

● 0-999999 instantaneous flow value

● 0-9999999999.9999 cumulative value

● -9999~9999 temperature compensation

● -9999~9999 pressure compensation value

7. Protection methods

● Accumulated value retention time after power outage is greater than 20 years;

● Automatic reset of power supply under voltage;

● Automatic reset for abnormal work (Watch Dog);

● Self recovering fuse, short circuit protection.

8. Operating environment

● Environmental temperature: -20~60 ℃

● Relative humidity: ≤ 85% RH, avoid strong corrosive gases

9. Power supply voltage

● Conventional type: AC 220V% (50Hz ± 2Hz);

● Special type: AC 80-265V - Switching power supply;

● DC 24V ± 1V - Switching power supply;

● Backup power supply:+12V, 20AH, can maintain for 72 hours.

10. Power consumption

● ≤ 10W (powered by AC220V linear power supply)

Product Interface

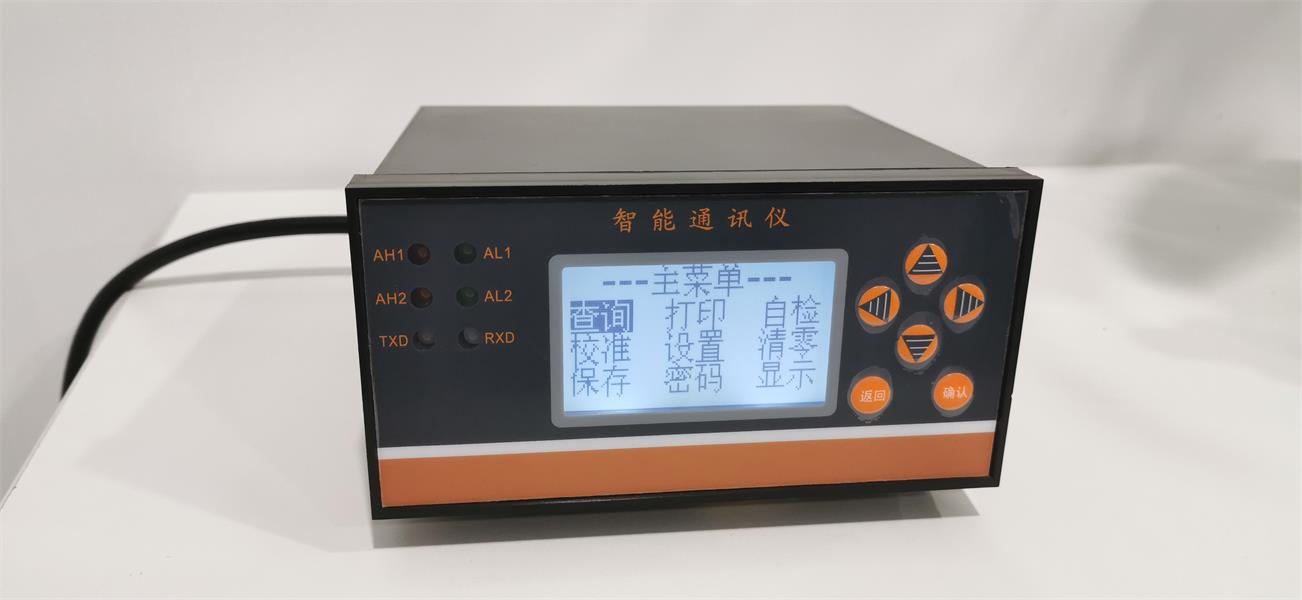

Note: When the instrument is first powered on, the main interface will display (querying the instrument...), and the communication receiving light will flash continuously, indicating that it is not connected to the primary instrument with wires (or the wiring is incorrect), or not set as required. The parameter setting method for the communication instrument refers to the operating method. When the communication instrument is connected to the primary instrument wires normally and the parameters are set correctly, the main interface will display the data on the primary instrument (instantaneous flow rate, cumulative flow rate, temperature, pressure).

The types of flow meters include: vortex flow meter, spiral vortex flow meter WH, vortex flow meter VT3WE, electromagnetic flow meter FT8210, Sidas easy correction instrument, Angpole square meter head, Tianxin flow meter V1.3, thermal gas flow meter TP, volumetric flow meter, electromagnetic flow meter WH-RTU, electromagnetic flow meter MAG511, heat integrator, thermal gas flow meter, spiral vortex flow meter, flow integrator V2, and flow integrator V1. The following two lines are communication settings prompts. Please refer to the settings here for the communication parameters of the flowmeter. The table number is the communication address, 9600 is the communication baud rate, N represents no verification, 8 represents 8-bit data bits, and 1 represents 1-bit stop bit,. On this interface, select the flow meter type by pressing the up and down keys. The communication protocol between the spiral vortex flow meter, gas turbine flow meter, and gas waist wheel (Roots) flow meter is consistent.

Communication method: RS-485/RS-232/broadband/none;

The effective range of the table number is 001 to 254;

Baud rate: 600/1200/2400/4800/9600.

This menu is set for communication parameters between the communicator and the upper computer (computer, PLC), not for communication settings with the primary meter. When setting, press the left and right keys to move the cursor position, and use the up and down keys to change the value size.

Display unit selection:

The instantaneous flow units are: m3/h g/s、t/h、kg/m、kg/h、L/m、L/h、Nm3/h、NL/m、NL/h;

Accumulated flow includes: m3 NL、Nm3、kg、t、L;

Pressure units: MPa, kPa.