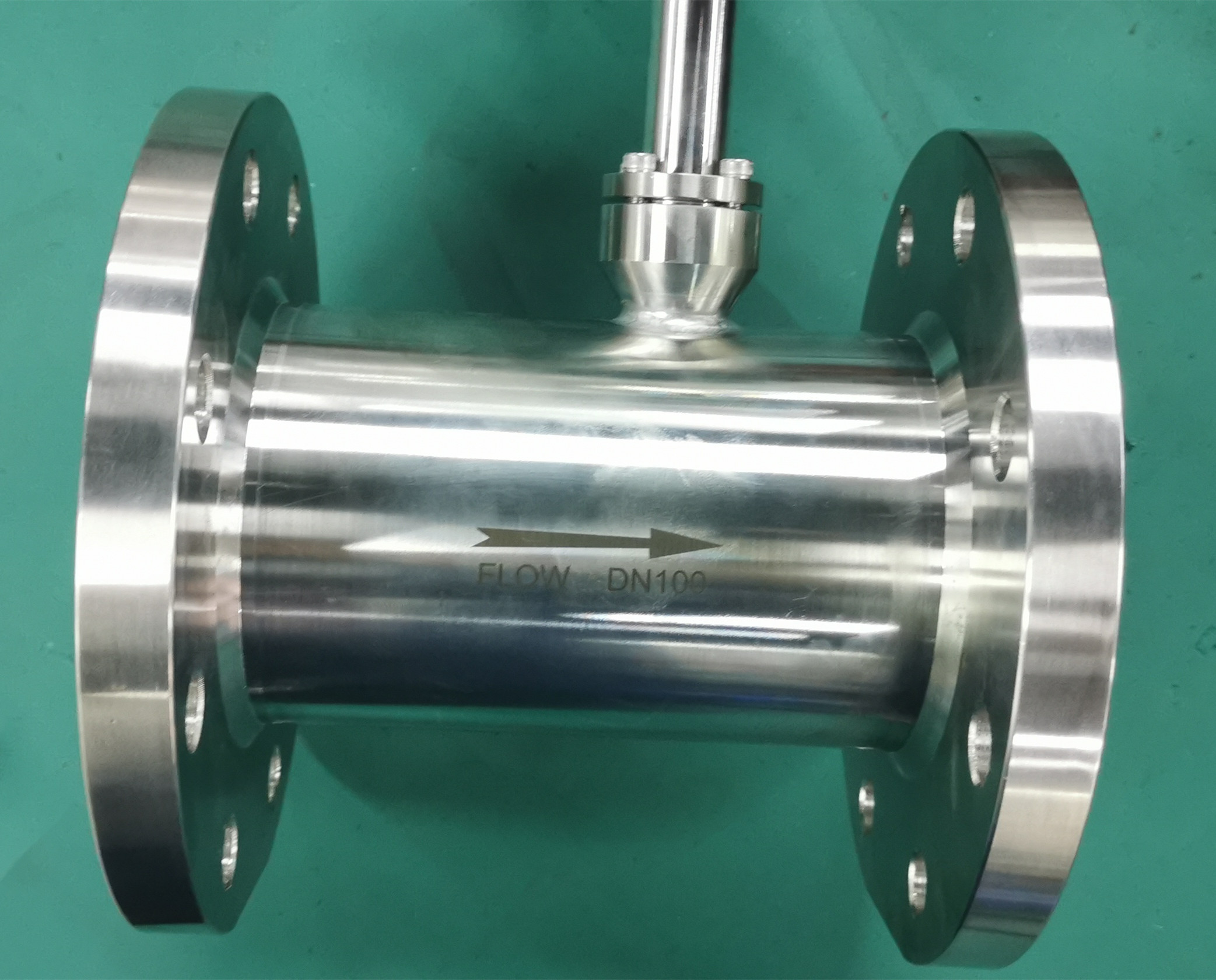

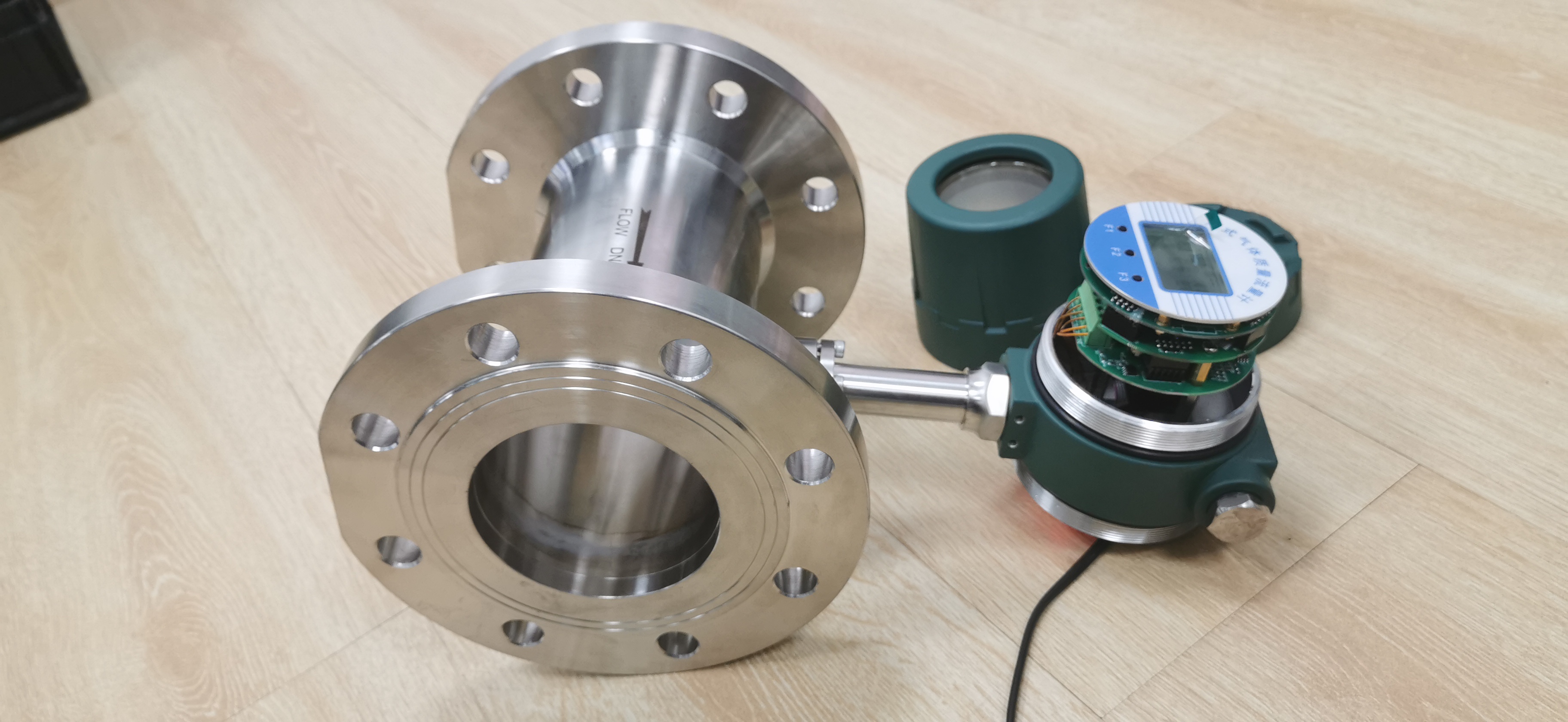

Pipeline type thermal gas mass flowmeter

Main Features

Product Advantages

Application Scenarios

Thermal gas mass flowmeter is based on the principle of thermal diffusion, which determines the gas mass flow rate by measuring the cooling effect of gas on the heat source. It has the advantages of high accuracy, wide measurement range, and fast response speed, and is widely used in multiple fields. The following are some specific applications:

Petrochemical industry

Accurate control of reaction feed rate: In the petrochemical production process, many chemical reactions require precise control of the feed rate of various gas raw materials to ensure the smooth progress of the reaction and stable product quality. Thermal gas mass flow meters can accurately measure gas flow in real-time, providing accurate flow signals for control systems and achieving precise control of reaction feed rates.

Monitoring process gas flow rate: In chemical processes, it is necessary to monitor the flow rate of various process gases to ensure the safe and stable operation of the process. For example, in the production of synthetic ammonia, it is necessary to monitor the flow rate of gases such as hydrogen and nitrogen. Thermal gas mass flow meters can meet this requirement and are not affected by changes in gas pressure and temperature, providing accurate flow measurement results.

Power industry

Monitoring boiler combustion air volume: During the boiler combustion process, it is necessary to accurately control the ratio of air volume to fuel volume in order to achieve ***** combustion effect, improve combustion efficiency, and reduce pollutant emissions. A thermal gas mass flowmeter can accurately measure the amount of combustion air entering the boiler, providing key parameters for the combustion control system and achieving optimized control of the combustion process.

Measurement of cooling gas flow rate for generators: Large generators typically use gas cooling methods, such as hydrogen cooling or air cooling. In order to ensure the safe operation of the generator, it is necessary to monitor the flow rate of the cooling gas in real time to ensure good cooling effect. The thermal gas mass flowmeter can accurately measure the flow rate of cooling gas, timely detect abnormal conditions in the cooling system, and ensure the normal operation of the generator.

Environmental Protection Industry

Monitoring industrial waste gas emissions: In industrial waste gas emissions monitoring, it is necessary to accurately measure the flow rate of various gases in the waste gas to evaluate the pollutant emissions of the enterprise and ensure that it meets environmental standards. Thermal gas mass flowmeter can measure various gases in exhaust gas without being affected by factors such as complex exhaust gas composition and high humidity, providing accurate data support for environmental monitoring.

Control of aeration process in sewage treatment plants: The aeration process in sewage treatment plants promotes the growth and metabolism of microorganisms by introducing air into the sewage, thereby achieving the degradation and removal of organic matter in the sewage. Thermal gas mass flow meters can accurately measure the flow rate of air during the aeration process. By controlling the flow rate, precise adjustment of aeration intensity can be achieved, improving sewage treatment efficiency and reducing energy consumption.

Pharmaceutical industry

Gas flow control in drug production process: In the drug production process, many process steps require precise control of gas flow, such as controlling the flow of dry air, sterilization gas, etc. during drug drying, sterilization, etc., to ensure the quality of drugs and the safety of the production process. Thermal gas mass flow meters can meet the precise control requirements of the pharmaceutical industry for gas flow, providing reliable guarantees for drug production.

Laboratory gas flow measurement: In pharmaceutical laboratories, thermal gas mass flow meters are commonly used for gas flow measurement in various experimental processes, such as gas feed control in chemical reactions, gas purging of experimental equipment, etc. Its high precision and reliability help researchers accurately grasp experimental conditions, improve the accuracy and reproducibility of experimental results.